In the fast-evolving landscape of global manufacturing, obsolescence management is no longer a secondary consideration—it’s now a core component of a resilient and future-focused strategy. As products become more complex and supply chains more integrated, proactively mitigating the risks associated with obsolete parts, materials, and technologies is critical to maintaining operational continuity and customer satisfaction. With 2025 on the horizon, manufacturers must upgrade their obsolescence management playbook to remain competitive.

Obsolescence doesn’t just mean outdated technology—it includes components that are no longer available, software platforms that are no longer supported, and machinery that can’t be serviced. Without strategic planning, such risks can drive up costs, delay production, and harm customer relationships. Below are six key obsolescence management strategies that every manufacturing company should implement in 2025 to ensure efficiency, foresight, and agility.

1. Proactive Lifecycle Forecasting

One of the cornerstones of good obsolescence management is understanding the lifecycle of your components and materials. Companies that wait for a part to become obsolete before reacting are already losing time and money. Instead, they should adopt proactive forecasting techniques that rely on supplier data, historical trends, and predictive analytics.

- Use industry-recognized lifecycle prediction tools.

- Create a component database that tracks each item’s age and support status.

- Collaborate with suppliers to obtain End-of-Life (EOL) notifications.

Early warnings allow procurement and engineering teams to seek alternatives or bulk purchase remaining stock, keeping operations seamless.

2. Establish Cross-Functional Obsolescence Teams

Obsolescence management should not fall solely on procurement or engineering. Highly effective organizations understand the need for a dedicated, cross-functional obsolescence team comprising members from:

- Procurement

- Product design and R&D

- Maintenance and operations

- IT and supply chain management

The cross-disciplinary nature of obsolescence affects multiple departments. For example, software upgrades could necessitate hardware compatibility reviews or vice-versa. Cross-functional teams can catch such interdependencies early and craft joint responses before they turn into production-halting issues.

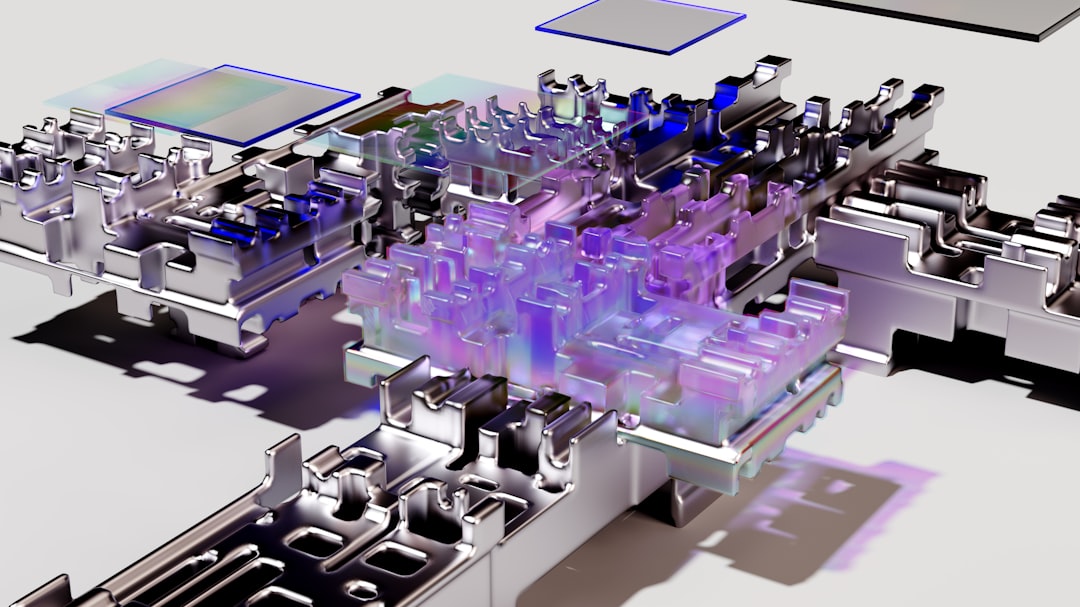

3. Digital Twin and Simulation Modeling

Digital transformation isn’t just a buzzword—it’s the foundation for smarter obsolescence management in 2025. Using digital twins—virtual replicas of physical assets—companies can simulate part removal, design updates, or substitutions in real time before actual implementation.

This practice allows engineers and planners to:

- Visualize how part replacement impacts entire systems.

- Predict failure points and plan preventive maintenance.

- Evaluate long-term implications before placing new orders.

Incorporating simulation modeling helps companies reduce the trial-and-error approach traditionally applied to changeovers, saving time and preserving system integrity.

4. Supplier Relationship and Risk Management

Strong relationships with suppliers can pay dividends when it comes to obsolescence warnings and mitigation. By maintaining transparent and collaborative ties with suppliers, manufacturers can often get advance notice of upcoming changes or phaseouts.

This strategy includes:

- Negotiating access to EOL and Product Change Notifications (PCNs)

- Securing last-time buy (LTB) agreements before phase-outs

- Conducting joint risk assessments regularly

Moreover, creating supplier scorecards that factor in obsolescence performance adds accountability and clarity in ongoing supplier evaluation processes.

5. Investing in Component Alternatives and Reverse Engineering

Despite the best foresight, some obsolescence will be inevitable. That’s why it’s smart to build a top-down strategy for identifying functional equivalents and reverse engineering critical components.

- Maintain a pre-vetted list of secondary suppliers.

- Invest in in-house redesign capabilities, enabling re-engineering of outdated elements.

- Use 3D design software and additive manufacturing (such as 3D printing) to create limited runs of obsolete parts.

Reverse engineering is especially crucial in defense, aerospace, and other sectors where formal replacements may no longer be produced due to regulatory or technological shifts.

6. Standardization and Modular Design

Manufacturers aiming at long-term efficiency should integrate standardization and modular thinking into their product design. This approach not only minimizes complexity but also simplifies future replacements and upgrades.

Key benefits include:

- Interchangeable modules reduce dependency on a single source.

- Improved inventory efficiency by limiting variety across products.

- Easier upgradability and less expensive maintenance cycles.

Incorporating modular design from the outset ensures that companies are not locked into specific suppliers or obsolete platforms, giving them agility to pivot as market conditions shift.

Conclusion

Obsolescence is an unavoidable aspect of manufacturing, but with the right strategies, it can be anticipated and managed with minimal disruption. In 2025, successful manufacturing companies will not only react to obsolescence—they will plan for it. Through lifecycle forecasting, digital tools, supplier relationships, and agile design, organizations can build resilience into their operations and create competitive advantages.

Implementing the above strategies enables manufacturers to protect profitability, extend product lifecycles, and meet customer expectations in an increasingly complex supply landscape. The key is starting today.

Frequently Asked Questions (FAQ)

What is obsolescence in manufacturing?

Obsolescence in manufacturing refers to when a part, material, or system becomes outdated or unavailable, making it difficult or impossible to maintain or build products as originally designed.

Why is obsolescence management important in 2025?

With rapid technological advancements and global supply chain disruptions, managing obsolescence in 2025 is critical to ensuring continuity, reducing costs, and avoiding production delays.

How does a digital twin help in managing obsolescence?

A digital twin allows manufacturers to model and simulate potential changes such as part substitutions, helping to foresee the effects on broader systems before physical changes are made.

Can reverse engineering replace every obsolete component?

While reverse engineering can provide solutions for many discontinued parts, it depends on the complexity and regulatory factors surrounding the component. It is most viable for mechanical parts, less so for proprietary electronics or software.

What role do suppliers play in obsolescence management?

Suppliers are crucial allies. They can provide early warnings, offer last-time-buy opportunities, or suggest alternative components. Strong supplier relationships facilitate proactive risk management.

How does modular design combat obsolescence?

Modular design makes it easier to replace individual components without redesigning an entire system. It enhances flexibility and reduces the risks associated with single-point dependencies.